Macchina automatica per sigillare l'etichettatura della tappatura del riempimento dell'olio del macchinario dell'attrezzatura dell'olio da cucina del motore d'oliva da 150ml a 1000ml

Dimensioni confezione 180,00 cm * 200,00 cm * 180,00 cm Peso lordo confezione 500,000 kg Da 150 ml a 1000 ml Olio da cuc

Invia la tua richiestaDESCRIZIONE

Informazioni basilari.

| Modello numero. | SD-YTGZJ |

| Grado automatico | Automatico |

| tipo di materiale | Liquido |

| Testa della valvola di riempimento | Multitesta |

| Struttura del cilindro di alimentazione | Alimentazione multistanza |

| Dispositivo di dosaggio | Rotore |

| Principio di riempimento | Pressione |

| Struttura di sollevamento del contenitore di imballaggio | Sollevamento pneumatico |

| Struttura | Lineare |

| Confezione | Bottiglia |

| Materiale da imballaggio | Plastica |

| Componenti principali | Motore, recipiente a pressione, pompa, PLC, ingranaggio, cuscinetto |

| Pacchetto di trasporto | Scatola di legno |

| Specifica | Coperto con pellicola antistatica importata, rinforzata |

| Marchio | Nello spettacolo |

| Origine | Shangai |

| Codice SA | 8422301090 |

| Capacità produttiva | 1000 |

Imballaggio e consegna

Dimensioni imballo 180,00 cm * 200,00 cm * 180,00 cm Peso lordo imballo 500,000 kgDescrizione del prodotto

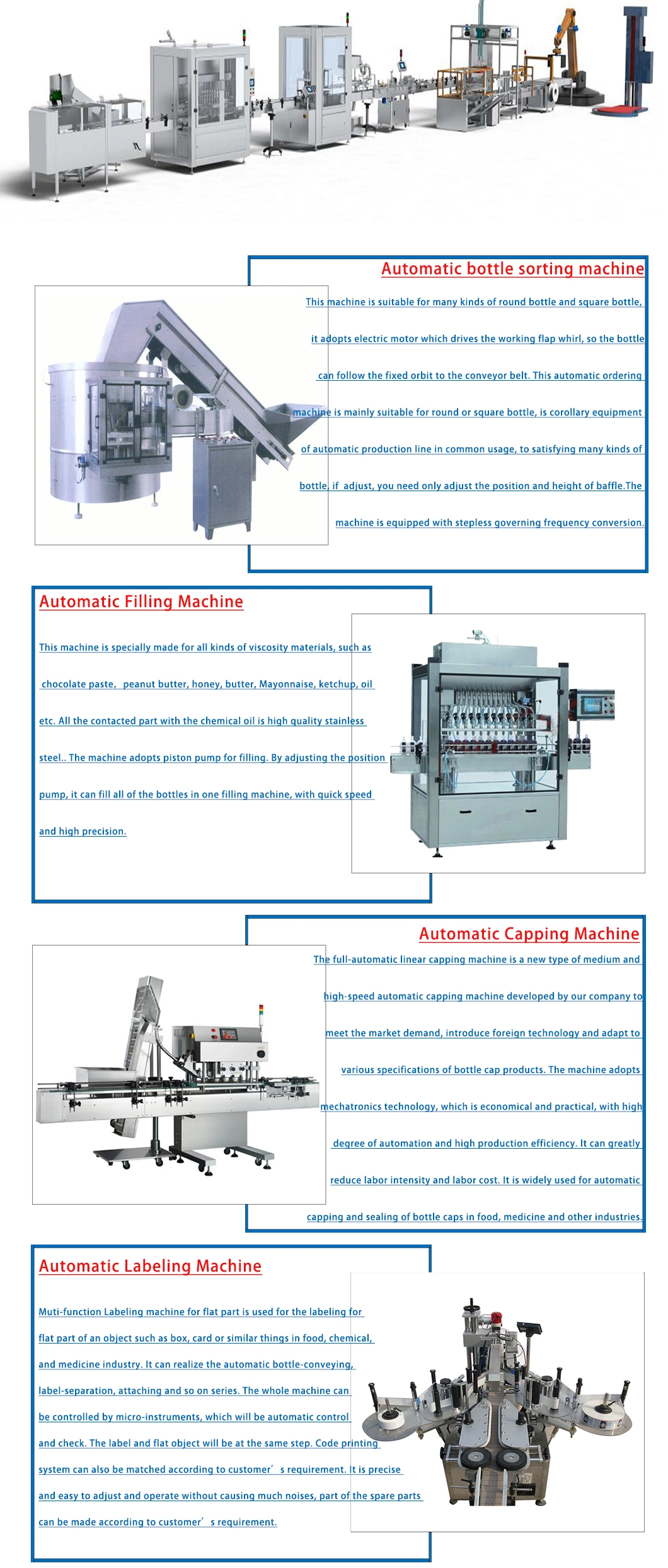

Olio da cucina automatico per motore d'oliva da 150 ml a 1000 ml Macchina per il riempimento dell'olio, la tappatura, l'etichettatura, l'etichettatura dei macchinariDescrizione del prodotto

Our service:Pre-sale: Accept your inquiries and organize special technical seminars to discuss customer equipment requirements. Provide you with a detailed "equipment plan", including:1. Equipment samples;2. The latest technology and technology of related equipment at home and abroad, and the comparison of the advantages and disadvantages of products of related manufacturers;3. GMP process design, plant water and electricity layout;4. Process design of mechanical equipment;5. Related product configuration, spare parts, packaging and after-sales service;6. Determine the equipment and quote item by item.On sale:1. Keep in touch with you at all times, invite customers to visit the company, and supervise production equipment;2. Prepare the equipment manual, file card and tracking card and other related software, and accept your acceptance at any time;3. Regularly report the production progress of the equipment to the customer.After-sales (operate according to the international standard after-sales service)1. One-year warranty, lifetime service, 24-hour after-sales service website, hotline and fax will be opened for you, and domestic customers will basically arrive at the designated location within 24-72 hours;2. The spare parts inventory is fully stocked for a long time, and the wearing parts, consumable parts and important accessories are guaranteed to respond to customers in the first time;3. Regularly return visits to each customer, once a year, and record the equipment file records.Our company's advantages: 1. The practicability of the equipment: The single machine designed and manufactured by Shouda Company has reliable quality, long service life, low failure rate and convenient maintenance. It can run for more than three to five years without failure under normal use. 2. The operability of the equipment: It is easy to operate, easy to learn and master, suitable for people with different educational levels. At the same time, the equipment is highly standardized and has a strong matching ability, which can easily and quickly replace various parts and components of different specifications. 3. Appearance of the equipment: The appearance design of the equipment is beautiful and generous, in line with ergonomic principles. No matter in terms of material, shape, color, or size ratio, we strive to be more humanized design, so that the appearance and internal quality of the equipment and mechanical performance. , achieve the most perfect unity. 4. Advanced equipment:A. The equipment realizes automatic unmanned operation from automatic bottle unscrambling, bottle washing, filling, sealing, capping, labeling, unpacking, packing, box packaging and other processes.B. Successfully solve the instant foaming, dripping and filling accuracy of filling.C. Successfully solve bottle mouth small-diameter filling and adopt vacuum filling method.D. Successfully developed leading technology in the industry HCF-134A filling machine.E. Adopt import high-quality filling pump.F. The magnetic capping method is adopted, which does not damage the cap and does not loosen.G. Successfully solve the problems of bottle feeding and out of the bottle, broken bottles and bottle pouring of special-shaped bottles.

Prodotti correlati

-

![Riempimento automatico della macchina confezionatrice per l'imballaggio delle bustine verticali Vffs per salsa/condimento/sale/masala/concentrato di pomodoro/olio/alimento/liquido/spezie/sale/caffè/miele]()

Riempimento automatico della macchina confezionatrice per l'imballaggio delle bustine verticali Vffs per salsa/condimento/sale/masala/concentrato di pomodoro/olio/alimento/liquido/spezie/sale/caffè/miele

-

![Confezionatrice per polveri Vffs Confezionatrice per sacchi di farina da 1 Kg]()

Confezionatrice per polveri Vffs Confezionatrice per sacchi di farina da 1 Kg

-

![Confezione di frutta e verdura Pollo Agnello Manzo Carne Prosciutto Salsiccia Macchina confezionatrice sottovuoto]()

Confezione di frutta e verdura Pollo Agnello Manzo Carne Prosciutto Salsiccia Macchina confezionatrice sottovuoto

-

![Cura della pelle Trucco Impermeabile Rotolo personalizzato Ologramma Oro Argento Lamina Timbratura UV Stampato Medicina farmaceutica Profumo cosmetico Etichetta adesiva autoadesiva]()

Cura della pelle Trucco Impermeabile Rotolo personalizzato Ologramma Oro Argento Lamina Timbratura UV Stampato Medicina farmaceutica Profumo cosmetico Etichetta adesiva autoadesiva